From instrument panels to door trim and consoles, Inteva designs, engineers and manufactures high-quality lightweight systems that meet the wants and needs of automakers and end consumers while reducing environmental impacts.

Our experienced designers provide visionary perspectives on how the interior of a vehicle can offer a luxurious environment and user experience. Our deep knowledge of the entire body system allows Inteva to bring those concepts to life through skilled engineering and advanced manufacturing technologies, and our unique InLiteTM service to smart lightweighting brings cost-efficient weight savings to interiors.

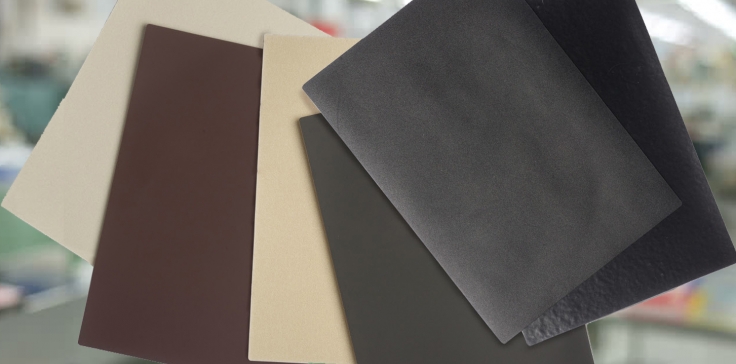

Inteva’s vertically integrated “pellets-to-parts” production of interior systems begins with leading-edge thermoplastic polyolefin (TPO) materials, including our own award-winning InteatherTM material, which can also be sold separately to other suppliers.

Featured Technology

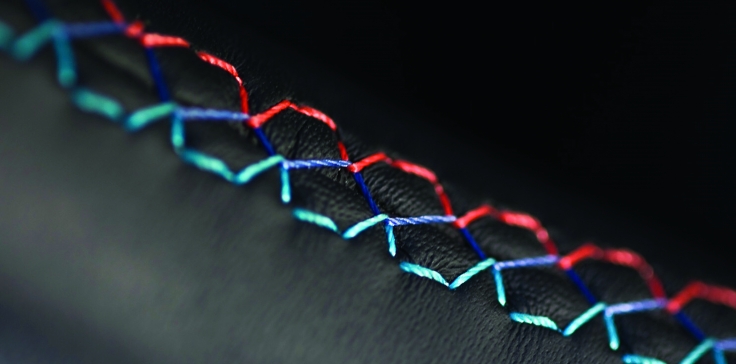

Robotic Stitching

Inteva has combined advanced sewing technologies with robotics to pioneer revolutionary stitching processes for manufacturing instrument panels and other large interior systems.

Our InStitchTM processes utilize programmed robotics equipment, patented sewing heads, and unique scanning methods adapted from other industries to provide a faster, more accurate alternative to the conventional cut, sew and wrap process. InStitch reduces scrap and cycle time. It also allows automakers to add a variety of unique stitches to places on the instrument panel surface where it would otherwise not be possible to do so.